Despite all configurability, sometimes the case arises that a need arises that is so specific that it cannot be met by any existing technology.

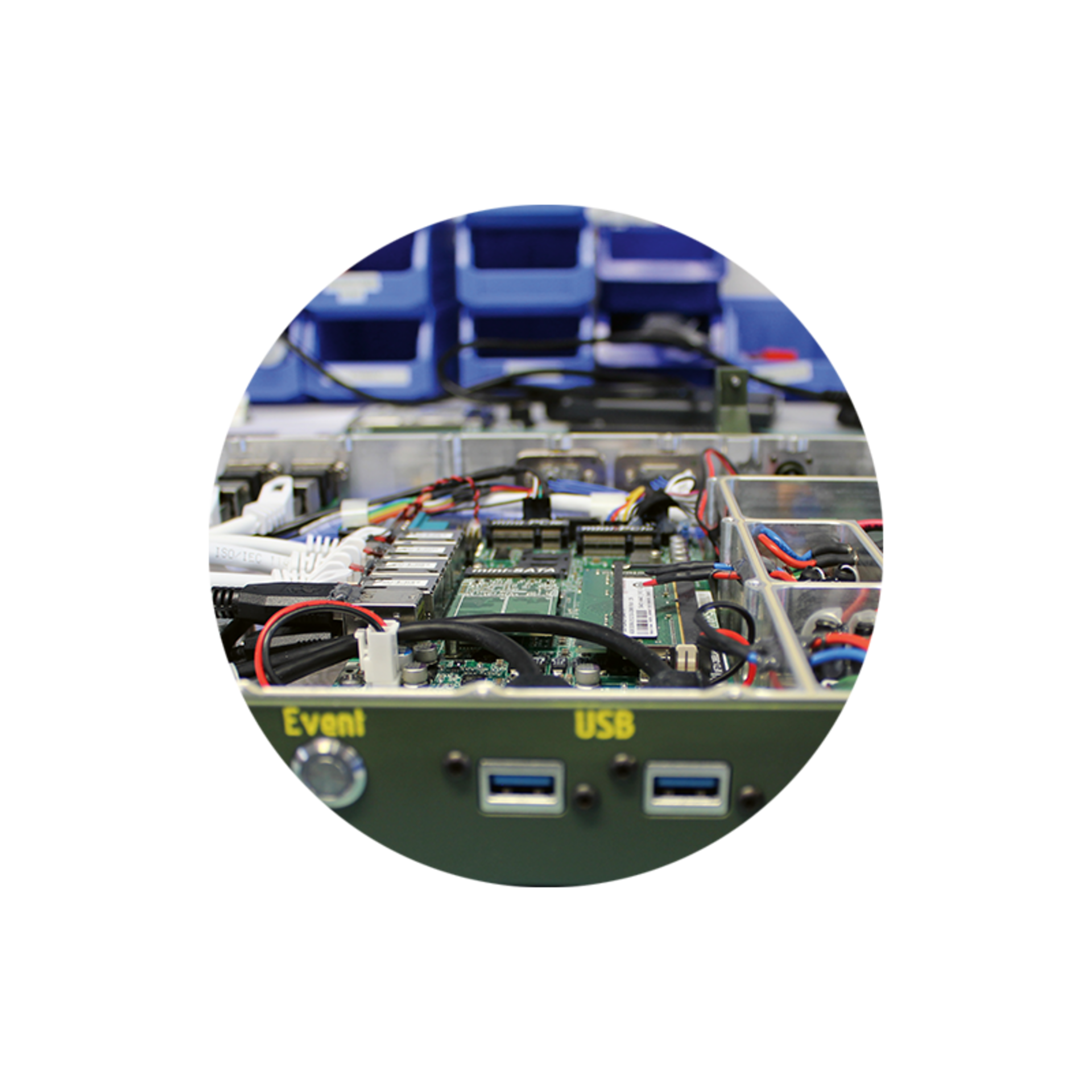

Such situations require not only real development competence, but also creativity and speed. This is what roda stands for and this is what roda has proven itself to be. From conception and design to electromechanical production by in-house resources, we take full responsibility for the timely and technically perfect implementation of the project.

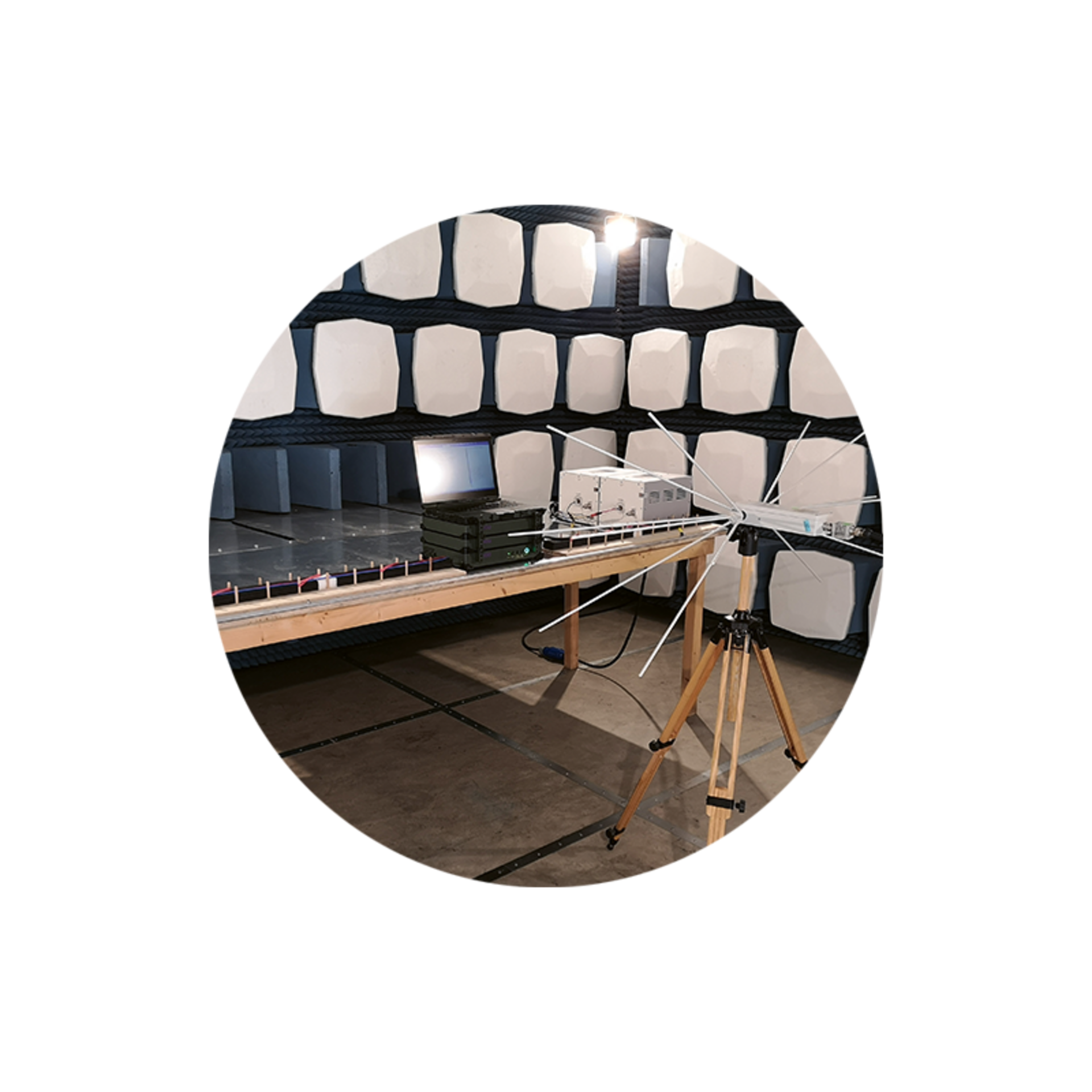

However, we do not go through this process alone - our customers as well as our suppliers are an important part of it. We involve them in a targeted manner in defined reviews to verify individual development steps, to confirm the required performance characteristics and to jointly determine the further procedure. Our flexible structures at roda make it possible for our customers to integrate their own procedures and specifications into the process and thus actively participate in shaping it. This is the path that has always led us to our goal - quickly and with maximum reliability.

Enquiry & requirement

It is not uncommon for specific hardware solutions to be needed, but there is no suitable hardware on the market that meets the necessary requirements.

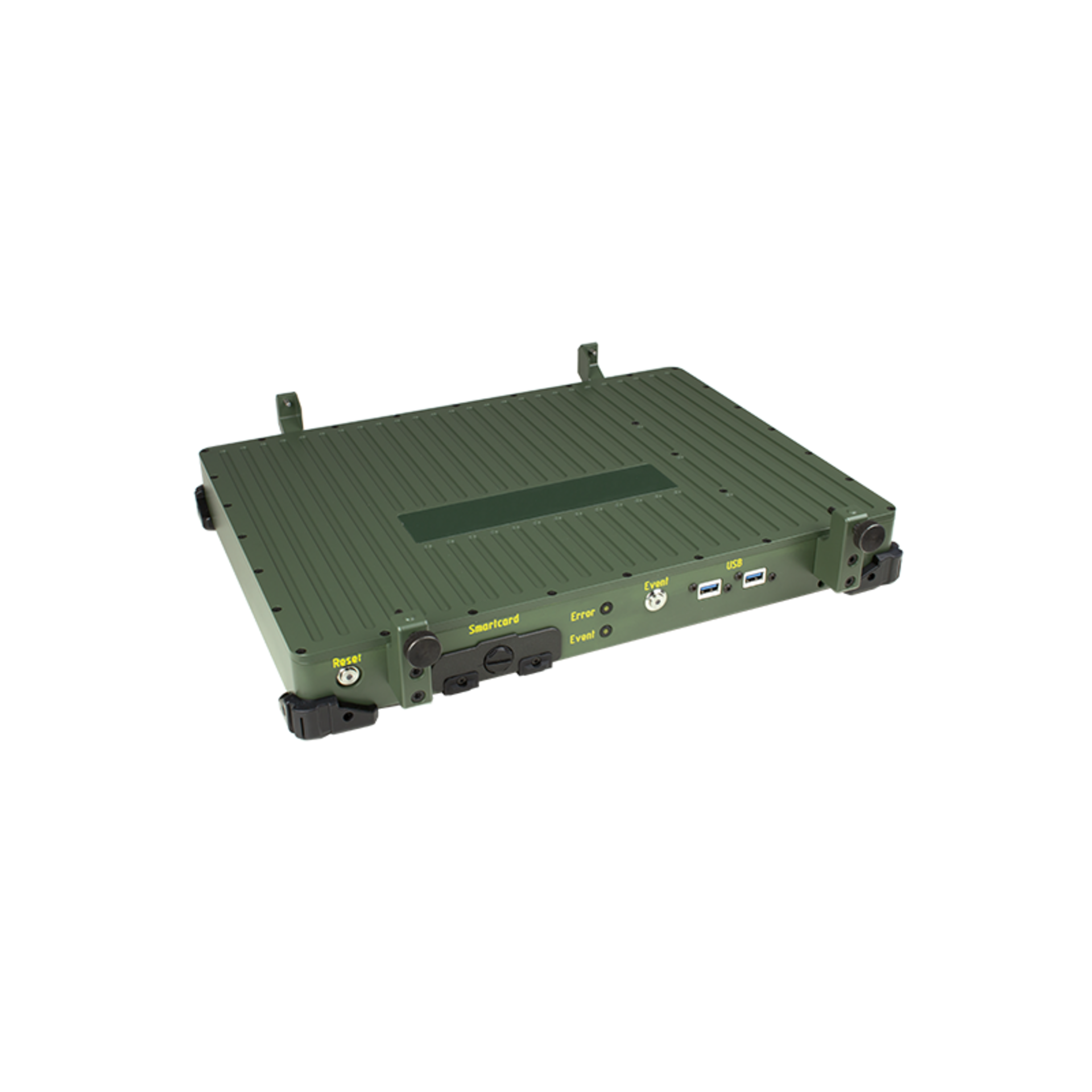

Ready for series production

Once all tests have been fulfilled, the final product can be manufactured and delivered to the customer. Depending on the size of the project, series production can then begin.

Many of our products are transferred to series production and are now an integral part of our product portfolio!